The Rothschild Performing Arts Center, due to open in February 2018, is designed to present a wide variety of wonderful shows to a comfortable audience, and there are a thousand elements, literally behind the scenes, that will enhance that experience. Here is a look at a few of the bigger elements that will make this center an outstanding performance venue for the Harker community for decades to come.

Architects for both the performing arts and athletic centers are Studio Bondy Architecture and Kevin Hart Architecture, which joined forces to design the gym and the theater, including the interiors and the site development, said Kevin Hart.

“As with any project of similar size, there is a large team of in-house architects and designers, consultants and sub-consultants,” he said, “in addition to the general contractor and subcontractors, who have important roles in the design and execution.” Of these many critical subcontractors, two play key roles in the development of the theater technology.

“The theater experts, The Shalleck Collaborative, worked as consultants to the architects to inform the design of the auditorium itself, the stage, rigging, theatrical lighting, orchestra pit, movable orchestra shell, control room, dressing rooms, and many other details,” noted Hart. “They also provided design of A/V systems, including the LED wall in the lobby.

“The acoustical experts, Charles M. Salter Associates, worked as consultants to the architects to design the acoustical qualities of the auditorium, which is adjustable for different uses. They also provided guidance for the acoustics in the rehearsal rooms and designed many of the wall and ceiling assemblies to prevent noise intrusion from outside and improve sound control between rooms.”

Display Wall

The most noticeable item attendees will see is the 34.5-foot-wide, 15-foot-high color LED display wall in the lobby. The display will showcase professional and student work. Once inside the building, the magic of technical theater won’t be as visible, but will provide for a remarkable audience experience.

Orchestra Pit Lift

One of the biggest and coolest pieces of equipment in the new facility is the custom-made, electromechanical orchestra pit lift. The lift is capable of raising and lowering the 48-foot-wide by 10-foot-deep elliptical segment of floor, 332 square feet in all, fully loaded. The segment can be used as a stage extension, for additional seating or as an orchestra pit.

Hart noted the lift platform is a steel superstructure with two interconnected heavy-duty motors which raise the platform on four “Spiralift” columns, Model #ND9, by Gala Systems.

These columns, fascinating pieces of machinery, are created anew each time the lift is used. Motors turn the column bases and a vertical steel band is locked into a spiraling horizontal steel band (picture a giant, high tech slinky) so the column “grows” as it goes up and is disassembled as it comes down, eliminating the need for a deep pit beneath the lift to house the column when in the down position.

Gala Systems noted the system is highly stable vertically and laterally, very quiet, nearly lubricant-free to eliminate any smell and should last the life of the facility with very little maintenance. The system is used in the Kennedy Center for the Performing Arts in Washington, D.C., and 55 countries around the world. Check out this video on how the system works: http://bit.ly/2yrGTEF. The lift will also be used to move the Bosendorfer concert grand piano from its stage-level closet to underneath the stage if needed. More about this wonderful piano in a future article!

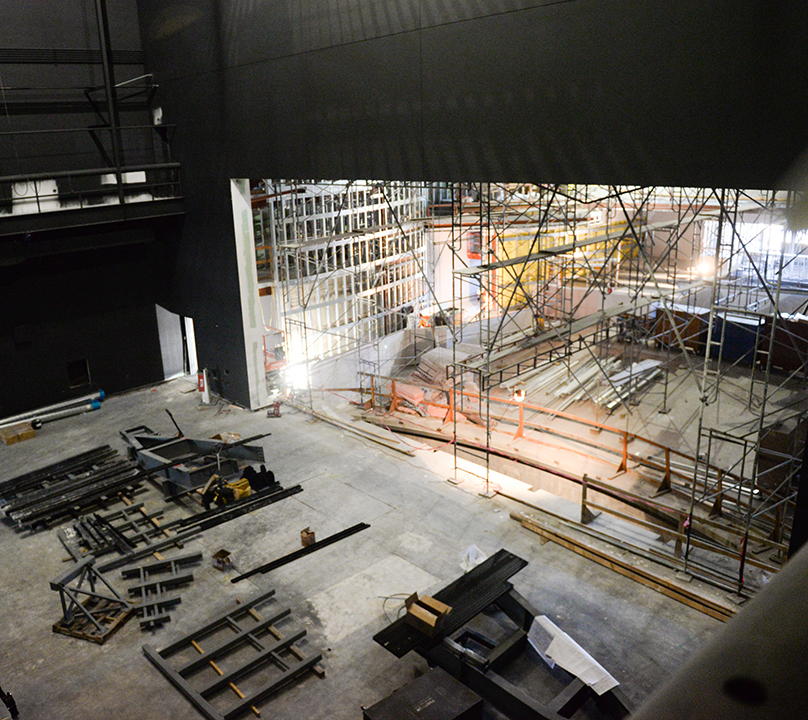

Professional Fly Tower

Another of the major components is the fly tower, containing 35 counterweighted rigging battens for moving scenery, lighting and special effects, and the top of the movable concert orchestra shell. Each batten can be used to raise an item, or they can be used together to raise larger items.

There are three battens for moving the top of the orchestra shell (the back and side pieces roll into place), five battens dedicated to stage lighting and 27 scenery battens, said Jedd de Lucia, a principal at The Shalleck Collaborative. The eight battens that control the orchestra shell and the lighting racks are motorized and can lift up to 2,800 pounds each, while the remaining 27 battens, capable of lifting 1,500 pounds each, are controlled by hand – the counterweights make it possible to move the relatively lightweight scenery up and down by hand. The rigging and lighting equipment is accessed via a series of perforated metal catwalks that run the width of the fly.

Sound and Acoustic Tuning

The main audio control console will be a Yamaha QL5 mixing board, said deLucia. This state-of-the-art soundboard was chosen for its versatility, ease of use and compact size. These soundboards are in use in many venues worldwide.

“The speaker system has a left and a right line array for the main PA speakers as well as supplemental ‘fill’ speakers at the front row as well as below and above the balcony,” noted de Lucia. The system uses the ARCS series of speakers from L’Acoustics, a French manufacturer of loudspeakers, amplifiers and signal processing devices, include ARCS-Series Wide and Focus speakers for main left and right speakers; SB18i subwoofers; X8 balcony fill speakers and 5Xt speakers for under-balcony and front fill speakers. The system is driven via 4-channel LA4X amplifiers. Full specifications can be found at http://www.l-acoustics.com/products-catalog-75.html

The center will have a custom-built, moveable orchestra shell enclosure to create a fuller, more directed sound, said Hart. “The shell consists of overhead ceiling reflectors and rolling wall towers, which will provide an excellent acoustic environment for music performances,” he said. “The theater will also have an audio-visual system to support amplified music and musical theater as well as a projection system for media presentations, including movies.

“Further, the acoustics of the hall can be adjusted for different kinds of performances, like acoustic music, amplified media and spoken word. The mechanism for this adjustability is made up of four banks of curtains, located out of sight above the ceiling, which can be pulled open or drawn closed to change the sound of the hall,” Hart noted.

Lighting, Trap and Curtain

The stage’s production lighting system uses LED stage lighting fixtures, without dimmers, on 96 relay-controlled circuits, and is capable of millions of colors at the touch of a button. The system will be run from the Electronic Theater Control Ion Lighting Console with a 2 x 20 fader wing, said de Lucia. Each batten is capable of carrying up to 50 lights, with a light about every foot along the lighting racks.

The trap, mid-stage, “is 12 removable pieces of the stage floor, which opens access to a room below the stage,” said Hart. “There is no elevator or lift; it will be up to the technical directors to build whatever device makes sense for each production. It could be as simple as a stepladder, or something more elaborate, but the main thing is to enable this special, magical capability to emerge from or disappear into the floor.”

The main curtain of the auditorium, with fabric from one supplier, sewn by a second and hung by a third, from is made of red velour, sewn with fullness. Curtains with fullness have extra fabric across the width or height of the drape. This gives the drape a richer look while increasing depth of field, and the heavy curtain provides more light and sound absorption.

That stage curtain is only a few months from swinging open for the first time. Watch for further updates each month as the Rothschild Performing Arts Center nears completion in February.